|

RecycleMichael

|

|

« Reply #15 on: October 22, 2007, 09:50:12 am » |

|

quote:

Originally posted by MichaelBates

Someone told me (maybe it was RecycleMichael) that because of clean air regulations, they can't make bricks nowadays as tough as the ones that were used for streets in the early 20th Century. Something about not being able to bake the bricks at a high enough temperature.

Didn't we learn our lesson from all the problems with the bricks on west 5th St.? How many more blocks of sidewalks could we fix downtown for the same money if we used concrete (with sparkly stuff mixed in for that diamond effect) instead of pavers?

Between the badly designed lighting and the overindulgence in brick, downtown streetscaping isn't working out as well as it should have.

Yes, it was me who told you that. I have a friend in Iowa who collects bricks (he has over 10,000 in his collection). The firing process for bricks is very regulated now and more expensive. The EPA has standards for the ovens that make it very difficult to make a good paving brick and the industry nows makes mostly architectural bricks. Clay vitrifies (melts) gradually under rising temperatures. If done properly, the resulting product becomes a solid mass with very low absorption. I am not an civil engineer, but my guess is that the base on which the bricks were placed allowed excess moisture from our wet summer to be absorbed by the bricks. I would want to test bricks from both projects for compressive strength and do an analysis of heavy vehicle traffic differences before I jumped to further conclusions. |

|

|

|

|

Logged

Logged

|

Power is nothing till you use it.

|

|

|

|

dsjeffries

Guest

|

|

« Reply #16 on: October 27, 2007, 05:52:29 pm » |

|

There was an article in the World the other day that mentioned the pavers in Brookside being replaced, but why don't they just do what they did to Delaware between 3rd & 11th??? They poured colored concrete crosswalks then stamped them to look like brick... Takes care of the crumbling paver problem, and lasts much longer... They're already set into a concrete base, so what's the problem with pouring concrete in there instead??

|

|

|

|

|

Logged

Logged

|

|

|

|

|

danno

Guest

|

|

« Reply #17 on: October 27, 2007, 06:01:28 pm » |

|

I agree with whomever said that the downtown brickwork better be superior to the brookside mess. They had half of brookside closed off for a whole summer for that sh*t, and it is still rough as a cobb, maybe even worse than before. I felt sorry for the businesses in the area, as some of them were probably forced to close as a result of the roadwork.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

TheArtist

|

|

« Reply #18 on: October 27, 2007, 11:24:57 pm » |

|

Worse than the fact that its falling apart imo lol, is that the crosswalks they came up with looked crappy. Whats with the mix of "bricks" with cement designs anyway? It looks rinky dink and cluttery.

All of that work, hassle, money and time for something that looks like crap and is falling apart to boot.

Honestly, Who designed this whole debacle? On the one hand its a minor concern for the city. But on the other, those poor businesses, and people driving through there, that had to suffer through all of that hassle for so long deserved better.

|

|

|

|

|

Logged

Logged

|

"When you only have two pennies left in the world, buy a loaf of bread with one, and a lily with the other."-Chinese proverb. "Arts a staple. Like bread or wine or a warm coat in winter. Those who think it is a luxury have only a fragment of a mind. Mans spirit grows hungry for art in the same way h

|

|

|

|

tim huntzinger

Guest

|

|

« Reply #19 on: October 29, 2007, 07:53:50 am » |

|

What is worse are the failing bricks injuring Tulsa Runners. I saw two hit the deck, one bounced up, the other was injured and required EMSA.  |

|

|

|

|

Logged

Logged

|

|

|

|

|

spoonbill

Guest

|

|

« Reply #20 on: October 29, 2007, 08:36:05 am » |

|

Originally posted by tim huntzingerWhat is worse are the failing bricks injuring Tulsa Runners. I saw two hit the deck, one bounced up, the other was injured and required EMSA.  In many cities brick and stone pavers work very well and require relativly little mantanance. In some cities, St. Louis is an excelent example, the brick pavers and cobble stone installed 100+ years ago are still performing well and require minimal mantance. The problem comes from the installation specifications given by the city. A layer of compacted decomposed granite at least 3 inches deep must be laid on an already compacted aggregate base. Sand is not a viable option as it will shift and flow. The Brookside applications were very poorly done, both in the brick and in the textured concrete applied. Our climate requires a better expansion joint system than was used. With a good winter, we should see nearly all of the outer brick work out of the ground. The city would be better to choose cobble stone as a barrier between the brick walkway and the existing pavement/asphalt. The extruded round top of the granite works very well to slow traffic and provides a space for the joint to expand without losing joint fill. most cobble has a shape and depth that, as a border, can help prevent the settling of surrounding brick. I would propose a visit to the Central West end of St. Louis to look at the cobble stone and brick work that has existed under heavy traffic for over 100 years. They also use granite slabs for curb and gutter. It's fascinating to see them do utility work, because they just lift the curb, pull the pavers, do the job and then replace. No concrete/asphalt, and the repair is ready to drive on immediately! NO ORANGE CONES! In fact, I would think the savings in ORANGE CONES would pay for the added expense in materials. I wonder how much an orange cone costs? I'll find out!   |

|

|

|

|

Logged

Logged

|

|

|

|

|

spoonbill

Guest

|

|

« Reply #21 on: October 29, 2007, 08:41:39 am » |

|

In fact, I would think the savings in ORANGE CONES would pay for the added expense in materials. I wonder how much an orange cone costs? I'll find out!

Wow!!!! Orange cone with blinking light $82.80. I'm in the wrong business. Anyone want to start a manufacturing company?

|

|

|

|

|

Logged

Logged

|

|

|

|

|

RecycleMichael

|

|

« Reply #22 on: October 29, 2007, 08:44:56 am » |

|

I thought orange cones were begat from orange barrels.

|

|

|

|

|

Logged

Logged

|

Power is nothing till you use it.

|

|

|

|

booWorld

Guest

|

|

« Reply #23 on: October 29, 2007, 06:05:39 pm » |

|

quote:

Originally posted by spoonbill

The city would be better to choose cobble stone as a barrier between the brick walkway and the existing pavement/asphalt. The extruded round top of the granite works very well to slow traffic and provides a space for the joint to expand without losing joint fill...

I agree. The places where people actually walk would be better if they were paved with relatively smooth concrete or asphalt. quote:

I would propose a visit to the Central West end of St. Louis to look at the cobble stone and brick work that has existed under heavy traffic for over 100 years. They also use granite slabs for curb and gutter. It's fascinating to see them do utility work, because they just lift the curb, pull the pavers, do the job and then replace. No concrete/asphalt, and the repair is ready to drive on immediately! NO ORANGE CONES!

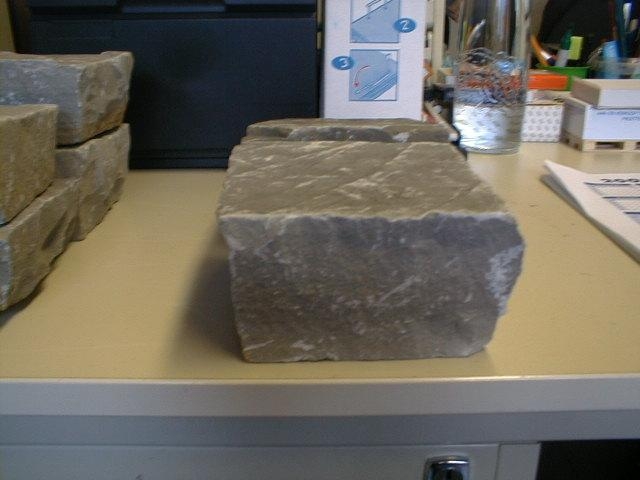

The photo appears to be granite settes. Was the photo taken in St Louis? I've seen granite settes in Europe, but not in this part of the United States. |

|

|

|

|

Logged

Logged

|

|

|

|

|

booWorld

Guest

|

|

« Reply #24 on: January 26, 2008, 10:36:07 am » |

|

quote:

Originally posted by ttown_jeff

Will every single sidewalk in downtown Tulsa be paved in brick?...

...What's wrong with concrete sidewalks?

Yesterday, to my surprise, I walked on a new concrete sidewalk at the southwest corner of 3rd and Boston (next to the 320 Boston Building). The new concrete is relatively smooth but not slick, and the surface appears to be sloped properly to direct water from the building toward the curb. I was thrilled to see this level of quality in new sidewalk construction downtown, because the unit pavers are failing in dozens if not hundreds of locations. I hope that the City and DTU will switch from unit pavers to concrete sidewalks, because the concrete is much more pedestrian-friendly. Also, from the moment they are installed, the unit pavers are a maintenance nightmare. |

|

|

|

|

Logged

Logged

|

|

|

|

|

booWorld

Guest

|

|

« Reply #25 on: February 26, 2008, 11:07:26 pm » |

|

|

|

|

|

|

Logged

Logged

|

|

|

|

|

TheArtist

|

|

« Reply #26 on: February 27, 2008, 09:40:58 am » |

|

I still prefer granite slab sidewalks. They last forever and when you need to repair something underneath, just lift em up, then put em back. They cost more short term but make up that extra cost at the time concrete or brick pavers need their first replacing, because they do not cost double. I remember the granite sidewalks in Paris. Aaaabsolutely flawless. 100 years from now... they will look, exactly, perfectly, the same. Even the best cement in our climate will start to go bad in only a few years. We could have done at least one street with them, Boston Ave for starters. Then each time other areas needed replacing, gradually add a bit more. Btw, I wonder if a rubber substrate would have worked better than sand for the brick pavers? The large brick area behind the Crowne Plaza is on a rubber substrate (over a parking garage, I know because I kept getting my car chased off of it while painting the Mayfest mural last year [  ]) and has been there for years. |

|

|

|

« Last Edit: February 27, 2008, 09:41:35 am by TheArtist »

|

Logged

Logged

|

"When you only have two pennies left in the world, buy a loaf of bread with one, and a lily with the other."-Chinese proverb. "Arts a staple. Like bread or wine or a warm coat in winter. Those who think it is a luxury have only a fragment of a mind. Mans spirit grows hungry for art in the same way h

|

|

|

|

sgrizzle

|

|

« Reply #27 on: February 27, 2008, 09:51:28 am » |

|

Strangely enough I noticed the new Centennial Green was putting in stamped concrete walkways leading to the DTU concrete pavers. Let's see if direct comparisons work.

|

|

|

|

|

Logged

Logged

|

|

|

|

|

Gaspar

|

|

« Reply #28 on: February 27, 2008, 10:23:02 am » |

|

quote:

Originally posted by TheArtist

I still prefer granite slab sidewalks. They last forever and when you need to repair something underneath, just lift em up, then put em back. They cost more short term but make up that extra cost at the time concrete or brick pavers need their first replacing, because they do not cost double. I remember the granite sidewalks in Paris. Aaaabsolutely flawless. 100 years from now... they will look, exactly, perfectly, the same. Even the best cement in our climate will start to go bad in only a few years. We could have done at least one street with them, Boston Ave for starters. Then each time other areas needed replacing, gradually add a bit more.

Btw, I wonder if a rubber substrate would have worked better than sand for the brick pavers? The large brick area behind the Crowne Plaza is on a rubber substrate (over a parking garage, I know because I kept getting my car chased off of it while painting the Mayfest mural last year [ ]) and has been there for years. ]) and has been there for years.

I agree! I used to live up in St. Louis and they use only Granite. Looks great and they can do street repairs easily! |

|

|

|

|

Logged

Logged

|

When attacked by a mob of clowns, always go for the juggler.

|

|

|

|

booWorld

Guest

|

|

« Reply #29 on: February 27, 2008, 06:40:37 pm » |

|

Good concrete can last for many decades. There are some 90-year-old concrete sidewalks in my neighborhood in good condition -- no need to rip them out.

Until recently, Boston had relatively smooth concrete sidewalks compared to the new rough and expensive unit paver sidewalks.

Granite slabs deserve serious consideration. Stamped concrete can be a good walking surface as long as the pattern is low relief. The rough simulated brick patterns are not good pedestrian surfaces. The plans for the streets and sidewalks downtown have been altered significantly. The previous design was better because it had fewer unit pavers, and pavers were not used for the primary walking surfaces or for crosswalks.

|

|

|

|

|

Logged

Logged

|

|

|

|

|